Sustainable Electronics

Topic Co-chairs: Thomas Okrasinski (Nokia), Fu Zhao (Purdue University), Pia Tanskanen (Nokia)

Contributing organizations: IBM, Nokia, Purdue University, University at Buffalo

Vision

The electronics life cycle stages from design manufacturing, operations (use cycle), and end-of-life has distinct societal and environmental effects. Resource extraction and processing often lead to habitat destruction and pollution. Manufacturing involves energy-intensive processes, contributing to greenhouse gas emissions, resource depletion and other eco-impacts. Distribution impacts transportation networks and global emissions. Usage influences energy consumption. End-of-life disposal poses e-waste challenges due to toxic substances and limited recycling. Collectively, these stages drive technological advancement and value for end-users, but also burden society with environmental degradation, resource scarcity, and waste management issues, underscoring the need for sustainable practices and circular economy initiatives.

In light of the ongoing climate challenges, the electronics industry is poised for a transformative shift driven by heightened consumer and corporate awareness of sustainable practices and circularity. An emerging fundamental change is the growing widespread integration of sustainability principles into the design and manufacturing of electronics. Modularity and design for sustainability will become the standard, ensuring products are easily repairable, upgradeable, and recyclable. This shift towards sustainable design will not only extend the lifespan of electronics but also minimize electronic waste and resource consumption.

The industry will adopt a proactive approach towards materials regulation, moving beyond compliance to anticipate and address potential environmental and health concerns. This will lead to innovations in process engineering and recycling chemistry, resulting in safer, more efficient, low-footprint methods for handling electronics throughout their lifecycle. A key aspect of this vision is the establishment of fully developed reuse and recycling supply chains. Automation, including robotics and artificial intelligence, will play a pivotal role in streamlining recycling processes, from disassembly to material recovery, fostering greater efficiency and accuracy in extraction of useful materials.

Ultimately, the electronics industry of the near future will embody a holistic and circular approach, where products are designed, manufactured, used, and recycled with environmental sustainability at the forefront. The alignment of consumer preferences, corporate responsibility, technological innovation, and robust recycling infrastructure and marketplace will propel the industry towards a greener and more resilient future, fostering a world where electronics not only enhance lives but also contribute to a more sustainable planet for generations to come.

Scope

Sustainability refers to the practice of utilizing resources, conducting activities, and making decisions in a way that meets the needs of the present without compromising the ability of future generations to meet their own needs. It involves striking a balance between environmental, social, and economic considerations to ensure a harmonious and enduring existence for both humanity and the planet.

There are three main elements of sustainability—sometimes referred to as “Planet, People and Prosperity,” described as follows:

Environmental Sustainability—This focuses on minimizing the negative impact of human activities on the natural world. It involves conserving resources, reducing pollution, and protecting ecosystems to ensure their health and longevity. Practices such as reducing greenhouse gas emissions, conserving water, preserving biodiversity, and using renewable energy sources fall under this pillar (“Planet”).

Social Sustainability—This aspect is concerned with promoting equitable and just societies where everyone has access to basic needs, human rights are respected, and opportunities for personal and collective growth are available. It involves addressing issues like poverty, inequality, education, healthcare, and social justice to create thriving communities (“People”).

Economic Sustainability—Economic sustainability entails managing resources and economic systems in a way that supports long-term prosperity. This involves promoting responsible consumption and production patterns, investing in innovation and technology, and ensuring that economic growth is not at the expense of environmental or social well-being (“Prosperity”).

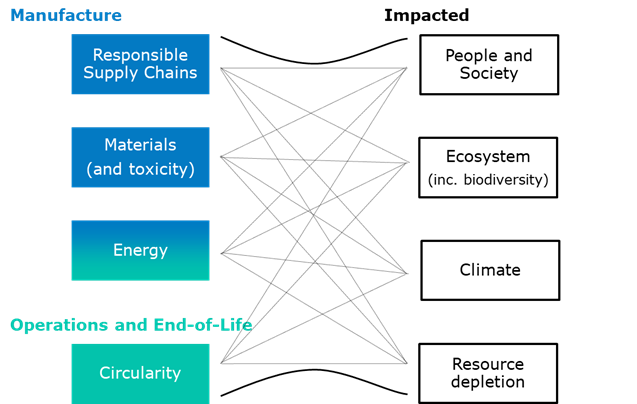

This topic is organized under the following technology areas:

Responsible supply chains

Energy and water consumption

As shown in Figure 1, each of these has impacts on the dimensions discussed above.

Figure 1. Electronics life cycle interdependent impacts on environment and society. Green implies being related to operations and end-of-life phases, blue relates to manufacturing phase.

Drivers

Driven by growing environmental concerns, resource limitations, and increasing awareness about the ecological impact of electronic waste, there is a pressing need to transition towards more sustainable practices within the electronics industry. This shift is catalyzed by a range of factors, including stringent regulations, consumer demand for eco-friendly products, and the realization that the traditional linear model of electronics production and disposal is no longer tenable. For key stakeholders, the application drivers are more specific as follows:

Consumers/service suppliers—Eco-conscious consumers are motivated by the prospect of minimizing their carbon footprint, conserving resources, and supporting ethical manufacturing practices. They are drawn to electronics that boast energy efficiency, longevity, and recyclability, aligning their purchasing decisions with their values for a greener future. Additionally, the assurance of reduced health risks due to less toxic materials in electronics enhances the appeal of sustainable options.

Embracing sustainable electronics enables suppliers to tap into new market segments and cater to the burgeoning demand from environmentally conscious consumers, thereby expanding their customer base.Government/regulatory agencies—These entities are increasingly driven by a pressing need to address the environmental and societal challenges posed by scarce resource access, e-waste and the broader impact of electronics on the environment. With the rapid pace of technological innovation and the widespread consumption of electronic devices, concerns about resource depletion, toxic material pollution, and the growing e-waste crisis have come to the forefront.1, 2 As a result, these agencies are motivated by the imperative to establish and enforce sustainable practices within the electronics industry. By doing so, they aim to reduce the eco-footprint of electronics manufacturing, curtail the hazardous chemicals used in production, and promote responsible disposal and recycling methods for end-of-life electronics. These drivers align with broader global goals, such as the United Nations' Sustainable Development Goals (SDGs)3, encouraging governments and regulatory bodies (and indeed the industry itself) to adopt stringent measures that ensure the longevity and environmental integrity of the electronics sector.

Shareholders—In sustainable electronics, all shareholders are increasingly motivated by a combination of ethical, financial, and strategic drivers:

From an ethical standpoint, shareholders recognize the pressing need to mitigate the environmental and social impact of electronic waste, aligning their investments with principles of responsible consumption and production.

Financially, the growing demand for eco-friendly electronic products and the implementation of efficient recycling processes present opportunities for companies to capture a larger market share and enhance long-term profitability.

Shareholders also recognize that embracing sustainability enhances brand reputation, fosters innovation in product design and manufacturing, and ensures compliance with evolving environmental regulations.

As the world shifts towards a more conscious and environmentally responsible paradigm, shareholders in sustainable electronics perceive their investments as a means to drive positive change while also securing robust financial returns.

Original equipment manufacturers/electronic manufacturing services (OEMs/EMSs)—are increasingly compelled by the application drivers in sustainable electronics to address environmental concerns, regulatory pressures, and shifting consumer preferences. As society places greater emphasis on eco-consciousness, OEMs and EMS companies recognize the imperative to minimize electronic waste, reduce carbon footprints, and enhance resource efficiency throughout the product lifecycle. Striving for product longevity, incorporating recyclable materials, and adopting energy-efficient production processes not only align with evolving regulations but also resonate with a growing market of environmentally-aware consumers.

Components and materials suppliers—The supplier community is propelled by a confluence of application drivers that underscore the critical importance of environmentally responsible practices. The urgent need to mitigate electronic waste and reduce resource depletion serves as a prominent motivator, compelling these suppliers to develop innovative solutions that promote product longevity, ease of recycling, and reduced toxic content. Additionally, the escalating demand for energy-efficient and eco-friendly electronics has steered suppliers towards materials and processes with lower carbon footprints, driving the adoption of renewable resources and cleaner manufacturing processes.

Reusers, refurbishers and recyclers—tap into the emerging financial, regulatory, and corporate incentives to mitigate the environmental impacts of e-waste while addressing resource scarcity and minimizing energy consumption:

Reuse offers the opportunity to extend the lifecycle of electronic devices, reducing the demand for new production and the associated resource extraction and emissions.

Refurbishment not only contributes to extending the usefulness of electronics but also promotes local job creation and skills development in repair and maintenance sectors.

Recycling, on the other hand, is crucial for recovering valuable materials from discarded electronics, curbing the depletion of finite resources and minimizing the environmental burden of improper disposal.

Dimensions of Sustainability

Circularity

Circularity within the electronics industry encompasses a growing movement to design, produce, and manage electronic devices life cycles in a way that minimizes resource consumption and waste generation. This involves strategies such as eco-design, repairability, component recycling, and responsible disposal. Industry players, policymakers, and consumers are increasingly recognizing the importance of circular practices to address the mounting environmental and resource challenges.

A detailed view of the needs, gaps, challenges and technology solutions for this topic is given here.

Materials

Material selection and utilization play a key role in developing sustainable electronics. Included are all of the materials involved in manufacturing electronic products, including those used in material processing, but not ending up in the final product. Sustainability issues could come from occupational exposure, environmental releases, and unreliable supply chains.

A detailed view of the needs, gaps, challenges and technology solutions for this topic is given here.

Responsible Supply Chains

Responsible supply chains play a pivotal role in promoting electronics circularity. Companies are increasingly focusing on sustainable sourcing, ethical labor practices, and environmentally conscious production to minimize electronic waste. By incorporating circular principles like recycling, refurbishment, and extended product lifecycles, these supply chains not only reduce the environmental impact of electronics but also foster a more resilient and resource-efficient industry.

Information on the drivers, needs, and challenges is currently being collected and will be published in 3Q2023. If you are interested in being notified when this is released, please email here.

Energy and Water Consumption

Industries are focusing on minimizing resource-intensive manufacturing processes and encouraging efficient use, repair, and recycling of electronic devices. Integrating energy-efficient production with responsible water management not only reduces the environmental footprint but also enhances the viability of a circular economy for electronics.

Information on the drivers, needs, and challenges is currently being collected and will be published in 3Q2023. If you are interested in being notified when this is released, please email here.

Conclusions/Recommendations

Sustainability in electronics stands on four pillars:

Technology and design

New technologies and approaches are needed to overcome the hardware and software limitations for reuse and remanufacturing and to find pathways for currently unusable and unrecyclable components.

A proactive design approach with circularity in mind can greatly ease the end-of-life management efforts, while not compromising on product reliability.

A full environmental and human health assessment is highly recommended when introducing new classes of materials.

Metrics and regulation

To enable the electronics ecosystem, in order to address the environmental drivers it is facing, industry consensus is needed for metrics and methodology—one suitable for electronics design, manufacturing and life cycle management remains to be established and standardized.

The understanding of environmental impacts is growing—it is no longer just the greenhouse emission, but material scarcity, water and land usage, etc. It is anticipated that this will result in restriction of more substances. As part of a proactive response, the industry needs to come together to create a consensus viewpoint for the industry on what are the environmental impacts of merit to target and work together to educate the global ecosystem/supply chain.

International disparities in legislation and regulation create fragmented markets. Harmonization of regulations and data reporting will help to overcome fragmentation issue

Faster standardization and adoption of digital product passport technologies and practices would encourage the development of new technologies for reuse, remanufacturing and recycling.

Supply chains and markets

Circularity requires significant changes to the manufacturing business model, likely from product-oriented to service-oriented, e.g., towards electronics-as-a-service.

To improve the current waste collection and recycling networks and to build markets for refurbished and remanufactured products, new business models need to be developed not just by the electronics industry but in conjunction with other stakeholders. Support for socio-economic analysis on key electronics application spaces is needed.

The electronics manufacturing industry needs to collaborate in supporting correct, sustainable supply chains. One example is that of the industry response to responsible sourcing of conflicting minerals. Refer to the Circularity section.

People

Leadership for change—the electronics industry should take the lead on the circularity transition and how electronics can help this. Workforce development and training of engineers in practice are needed to promote circularity. Efforts should be put into the development of new modules, courses, certificates (e.g., material toxicity; environmentally conscious manufacturing; lifecycle impact assessment; energy management in manufacturing, etc.), and programs.

Outreach to the public is also important to change consumer mindsets.

Your Feedback

We welcome your comments and suggestions! Here is a link for your input.

Go back to Sustainable Electronics Vision

Sustainable Electronics Acronyms

References

How the e-waste crisis is being fueled by disposable electronics (

https://www.unep.org/news-and-stories/story/how-disposable-tech-feeding-e-waste-crisis

Short-circuiting the electronic-waste crisis (

United Nations Department of Economic and Social Affairs, “The 17 Goals: Sustainable Development,” https://sdgs.un.org/goals, 2023.